Our Weigh Cells are used in all industrial production processes

In addition to integration in checkweighers and filling/dosing lines, they are also installed in packaging machines of all kinds. Weigh Cells prevaildue to:

- maximum accuracy

- guaranteed long-term stability

- excellent responsiveness

- first-rate linearty

- fastest settling times

Unshakeable – Weigh Cells for Production

Precision is the be-all and end-all when weighing products. Regardless of whether you manufacture pharmaceuticals, produce food or have to weigh chemical products – our Weigh Cells guarantee this precision when acquiring your product weights.

If you are looking for a technical solution with which you can achieve the highest quality in product manufacturing, enabling you to make an important contribution toward customer satisfaction, choose Wipotec Weigh Cells for a future-oriented investment.

You will notice that we understand our craft – the development and production of Weigh Cells – at the latest when you integrate one of our Weigh Cells into your automated and very fast production. Based on the principle of electro-magnetic force restoration (EMFR), Weigh Cells ensure precise weight measurements, even at very high speeds.

And in the event that your weighing process is subject to external influences, such as vibrations from adjacent production lines, here too you can rely on the most accurate data. Thanks to our Active Vibration Compensation (AVC), Weigh Cells filter out disturbance variables. For even greater reliability and product quality even in highly dynamic production processes.

Our weigh cell principle: fast and precise on principle

The basis of the rapid and exact working method of our Weigh Cells is the Principle of Electro Magnetic Force Restoration (EMFR). The basic principle is comparable to a simple beam balance. On request, Wipotec Weigh Cells can be fitted with AVC Technology (Active Vibration Compensation).

The Active Vibration Compensation (AVC sensor) provides you with exact measured values, without any loss of time or quality, even in demanding production environments.

Weigh Cell Finder – 3 steps to your solution

Our product finder will quickly navigate you to the right solution within our innovative weigh cell portfolio.

- Choose an industry

- Set product parametres

- Opt for your solution

Weigh Cell Overview

- 0-2 kg

- 0-15 kg

- 0-120 kg

- MTC

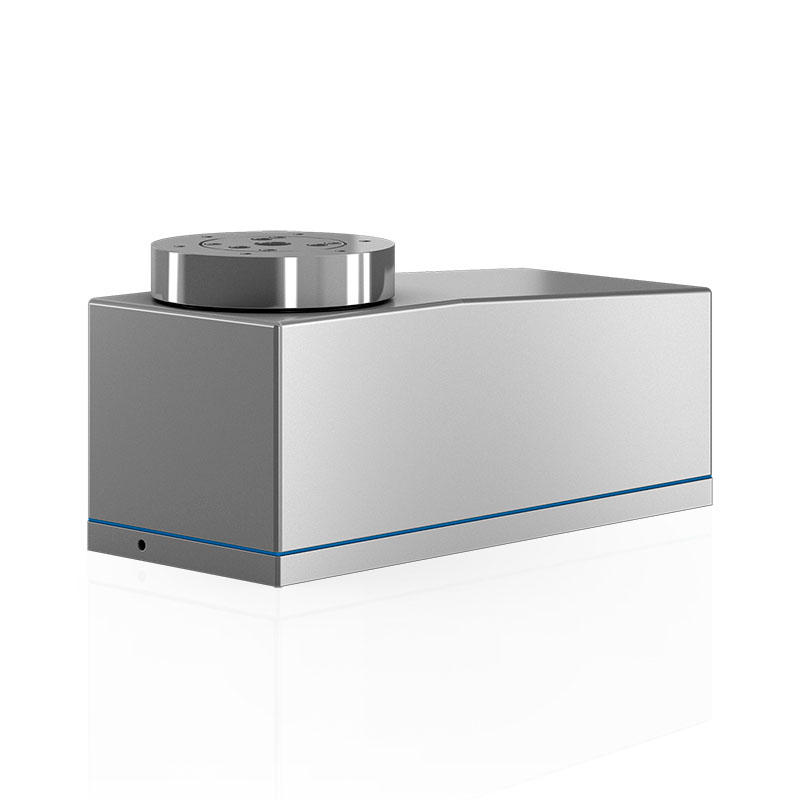

MMS 2

Weighing Range: 2,000 g

0-2 kg

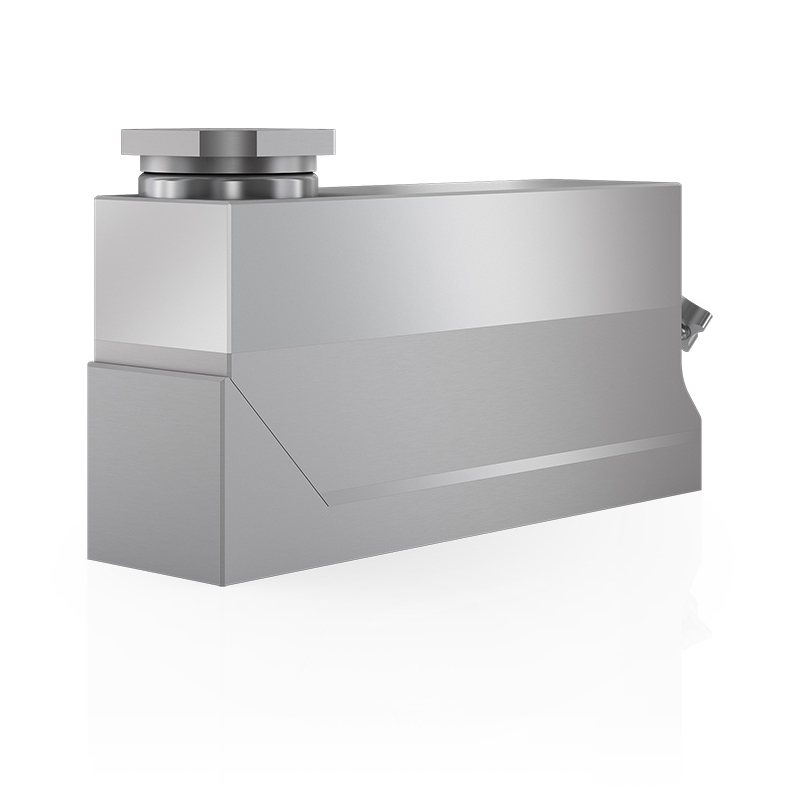

SX-M-FS

Weighing Range: 60 g

0-2 kg

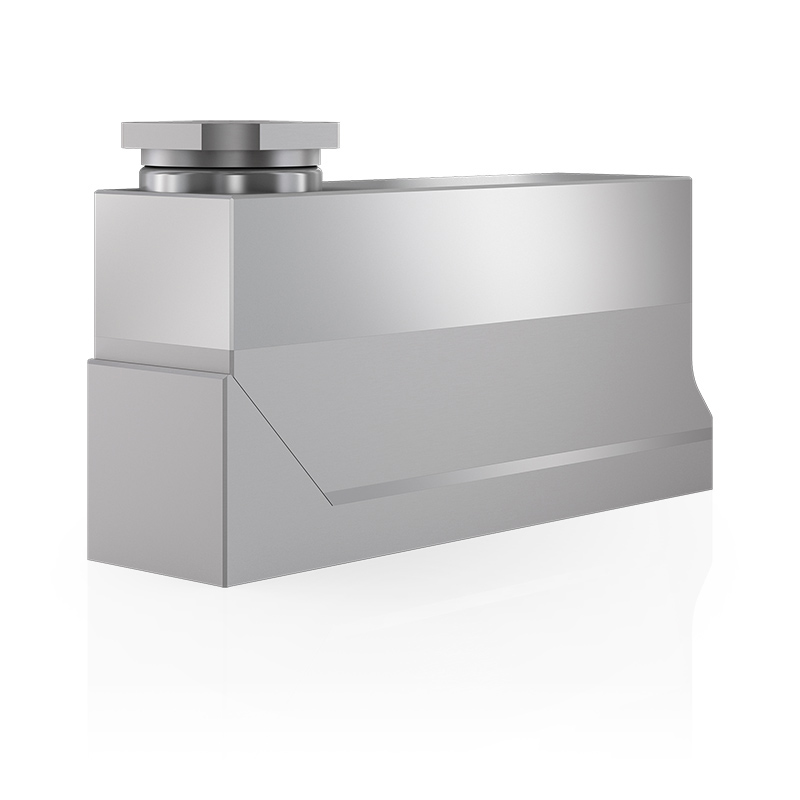

SL-M-FS

Weighing Range: 1,000 g

0-2 kg

SW-M-FS

Weighing Range: 2,000 g

0-2 kg

SL-E

Weighing Range: 70 g

0-2 kg

SL-FS

Weighing Range: 1,000 g

0-2 kg

SW-FS

Weighing Range: 2,000 g

0-2 kg

SW-D-FS

Weighing Range: 2,000 g

0-2 kg

SW-D-FS-EX

Weighing Range: 2,000 g

0-2 kg

SW-WD-FS

Weighing Range: 2,000 g

0-2 kg

EC-FS

Weighing Range: 15 kg

0-15 kg

EC-FS-AVC

Weighing Range: 7.5 kg

0-15 kg

EC-ES-FS

Weighing Range: 7.5 kg

0-15 kg

EC-FS-EX

Weighing Range: 15 kg

0-15 kg

IW-B-FS

Weighing Range: 120 kg

0-120 kg

MTC-AW-FS

Multitrack

MTC

MTC-FS

Multitrack

MTC

MTC-HL-FS

Multitrack

MTC

Industries

Weigh Cell FAQ

What is the difference between a Weigh Cell and a Load Cell?

Both Weigh Cells and load cells are used to measure weight; they are diverse in their technical design. The load cell version is based on measuring with a strain gauge which is mounted on a spring element. This principle is used when the time factor plays a subordinate role in weight measurement, such as in scales used in the retail sector. If it is necessary to weigh products within an automated, often very fast production process, Weigh Cells which work on the principle of electro-magnetic force restoration (EMFR) are used. They deliver precise weight measurements even at high speeds. It is possible to measure weights from as low as one (micro)gram or (milli)gram but also as high as 50 kg or 200 kg, for example.

How does a Weigh Cell work?

The classic design of a mechatronically complex Weigh Cell (EMFR) is made up of the balance mechanism, a position indicator, a controller, an electro-magnetic drive (coil and permanent magnet) and a display unit. For example, a CNC-machined monoblock, made of aluminum, can form the basis of the design. The Weigh Cell itself can be compared in its functionality to a simple beam balance: If a weight is placed on one side of the beam (coil arm), a coil attached to the opposite side of the weighing beam attempts to move out of the magnet's magnetic field. A photoelectric beam (zero indicator) detects this deviation and exactly the amount of current required for balancing the beam is transmitted through the coil. As the current is proportional to the weight and can be measured via a resistor, it can be converted into a digital signal which is used for further processing. This operating principle ensures that Weigh Cells which work according to the principle of electro-magnetic force restoration ensure high resolutions and good repeatability in equal measure and have short measuring times. The magnet system and the electronics, such as the scanning circuits, controller and filter boards, as well as specific communication interfaces, form the essential basis for extremely short settling times and sampling rates of 1 millisecond which are required above all in highly dynamic weighing processes.

Where are Weigh Cells and Load Cells used, respectively?

Depending on their design, Weigh Cells and/or Load Cells are used in almost all industries. Typical measuring tasks for strain gauges are acquiring the weight of a container on a one-off basis or continuous weighing, e.g. to record the inflow and outflow of a material into or out of a container (storage tank) using a load cell, as is required in the chemical industry, among others. Dynamic weighing and weight determination of difficult drugs, sensitive foods or the smallest electronic components using EMFR based Weigh Cells can be found everywhere in the manufacturing industry where the lowest weights correlate with the highest production speeds, such as in the automotive sector, electronics production, the pharmaceutical industry, food production or aerospace technology.

What types of load cells are there?

Load cells come in many different designs. Wipotec Weigh Cells are electromechanical systems, often with digital signal processing (evaluation electronics), which are used to measure forces or weights. We use them to manufacture weighing devices (scales). Depending on the type of scale, whether it is a platform, floor, tabletop or static scale, checkweigher or catchweigher, there are different types of Weigh Cells optimized for the particular application of the scale. Important parameters are accuracy, speed and type (tension, compression, dynamic, static), as well as the amount of the load.

The objects to be weighed pass by dynamic scales, such as checkweighers or catchweighers, at high speeds. They therefore require EMFR load cells that not only weigh accurately but also deliver results in a very short time. This means that, aside from precision, speed is the most important application parameter. These load cells, which include the Wipotec Weigh Cells, are generally constructed on the principle of electromagnetic force restoration (EMFR). Weigh Cells from Wipotec consist of a milled aluminum monoblock. They do not have a spring element that deforms under load but are based on a mechanical beam balance instead. Its minimal deflection is compensated electro dynamically. Wipotec Weigh Cells deliver highly accurate weighing results in a very short time. Mounted underneath platforms, they act as EMFR single point load cells to measure the compression load exerted. When mounted upside down, they can also measure tension forces.

Dynamic scales in particular, often have to cope with vibrations caused by the movement of the objects to be measured or by machines in the immediate vicinity. Wipotec's vibration compensating technology, AVC (Active Vibration Compensation), installed as an independent sensor or in the Weigh Cell itself, remedies this. AVC effectively filters out shocks and vibrations in all three spatial axes without loss in time or accuracy.

Weighing range and measuring accuracy, and frequently also the size or the mounting direction, are important application parameters for static scales, where the objects to be weighed are more or less at rest. The scales usually have a spring element; the mechanical force effect causes its deformation. Strain gauges, mounted on the spring element, detect the size of the deformation and convert it into an electrical signal. A commonly used spring element in bending beam load cells is the double bending beam, while shear beam load cells are suitable for higher loads. Column-type spring elements, deformed by compression, are referred to as compression force (compression) load cells. Single point load cells are mounted below the platform. S-shaped spring elements are used whenever tension forces need to be measured.

What is a digital load cell?

Digital load cells are a special type of load cell used to manufacture weighing devices, i.e. for weighing with scales. Digital load cells consist of digital signal processing and evaluation electronics. Two designs dominate when it comes to digital load cells: One has a spring element whose geometry changes slightly under the effect of weight. Strain gauges detect the elastic deformation in these digital load cells and convert them into an electrical signal. The second design principle uses a mechanical beam balance, the deflection of which is compensated electro dynamically by means of a plunger coil. Its measuring times are significantly shorter than those of digital load cells that operate with strain gauges.

Digital Weigh Cells from Wipotec operate according to the principle of electromagnetic force restoration (EMFR). The electromagnetic force restoration of a mechanical beam balance works with minimal deflection of the weighing beam, resulting in an extremely short settling time. This facilitates assessing the supported weight reliably and in a very short time. Digital signal processing combined with ultra-precise position regulators permits scanning intervals of one millisecond and thus the use of Weigh Cells in high-speed industrial processes. These are particularly common in the pharmaceutical, healthcare and cosmetics industries, as well as the food industry and in chemical manufacturing. In filling processes, they are especially used in the area of construction and mineral materials. High speeds are also important for courier, express and parcel services (CEP), in the mail order business and in intralogistics. The digital interfaces of the digital Weigh Cells are designed for communication with all control and fieldbus systems on the market. Wipotec's portfolio of digital Weigh Cells covers a measurement spectrum from one microgram to 120 kilograms.

Digital Weigh Cells are used in Checkweighers and Catchweighers, as well as X-ray Scanners and combination devices that combine weighing technology with X-ray systems (Weigh and Ray). All these systems are designed for high production speeds. Other areas of application are track and trace systems for pharma serialization and applications in logistics. In combination with metal detectors, they form space-saving combinations of checkweigher and metal detector system. Digital Weigh Cells from Wipotec are also integrated as original equipment manufacturer (OEM) components in packaging and filling machines.

Wipotec also offers digital Weigh Cells in Wash Down design. Special versions are suitable for use in potentially explosive areas or are equipped with AVC (Active Vibration Compensation).

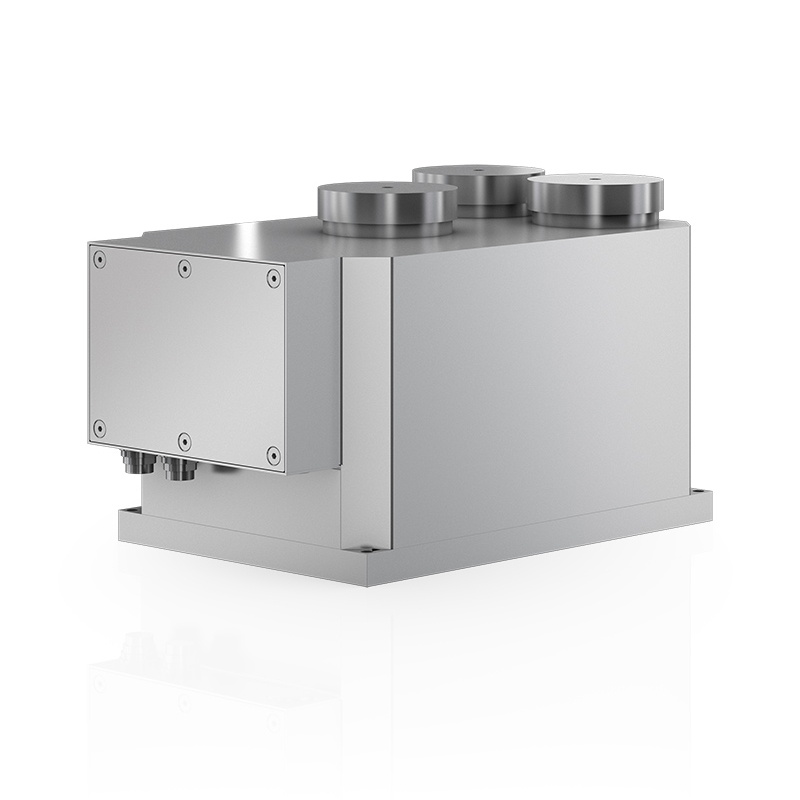

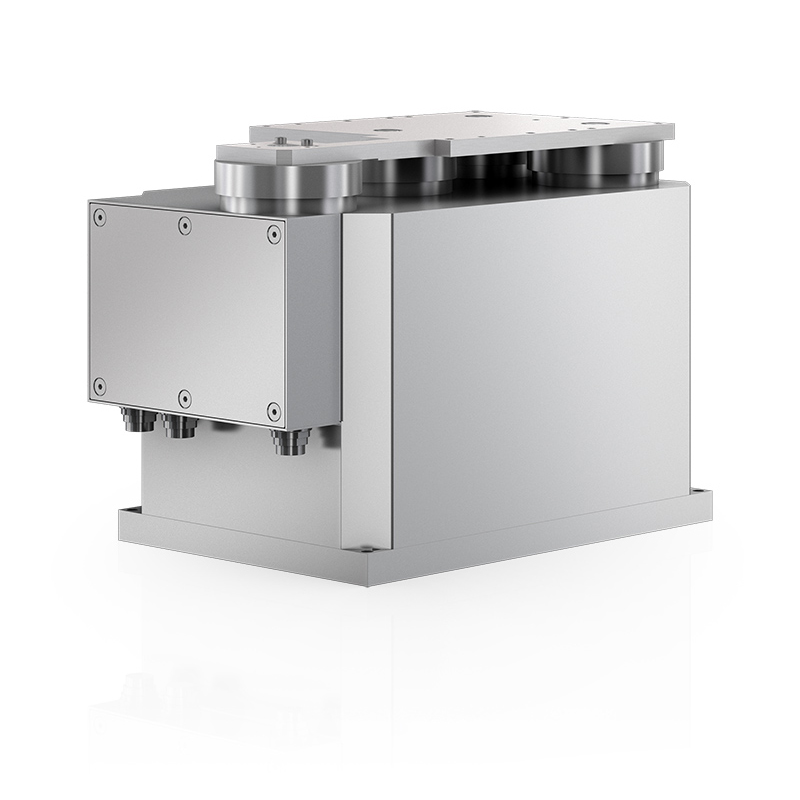

Digital multilane Weigh Cells

From a weighing perspective, digital multilane Weigh Cells from Wipotec can be supplied with electronics installed in a separate housing. Especially in multitrack applications, this prevents heat generation, which is harmful for fast and highly accurate weighing. Complex cooling is therefore not necessary.

As an alternative to the electronics box, the Wipotec Weigh Cells can be operated on MMS2 system components (MMS2 = Modular Multilane System). All components are designed with IP65 protection and do not need to be installed in a separate control cabinet.

If digital multilane Wipotec Weigh Cells are designed as Modular Multilane Systems (MMS2), they can be configured individually. A modular system at lane level enables the user to create a compact configuration of lane modules, with the electronic modules for Weigh Cells and AVC sensor mounted on top. An additional base module provides all connections for operating voltage, fieldbus, and analysis interfaces. The digital interfaces support all common fieldbus systems.

Digital multilane Weigh Cells can be equipped with AVC (Active Vibration Compensation); thus delivering reliable and accurate measured values even when exposed to severe vibrations, as they usually occur in multilane, fast-moving production plants. You will not need a separate scale frame with AVC technology. Digital multilane Weigh Cells are available with load output in front or on top.

What are single point load cells and where are they used?

Single point load cells are mainly designed for use in platform scales with one or more load cells. They are frequently employed in the food and pharmaceutical industries for filling, packaging, or weighing processes, where the focus is on high weighing speeds, robustness, and easy cleaning options. At low nominal load, single point load cells must be able to supply fast results for dynamic applications in order to be used in high-speed production lines of food-producing companies or in the high-speed systems of the pharmaceutical industry. In the e-mobility sector, single point load cells are used to weigh battery components, but also pharmaceuticals in the healthcare sector. Already packaged products are checked for completeness. In the chemical industry, single point load cells monitor manufacturing or filling processes. In belt scales, they are used for dynamic weight determination, for example in continuous bulk goods measurement.

EMFR single point load cells with their GMP compliant design are particularly suitable for use in dynamic applications of pharmaceutical production plants and in food sectors. Designed according to the principle of electro-magnetic force compensation, the single point load cells are very compact and therefore suitable for installation in multi-lane applications or wherever small sizes or small lane center to center distances are required. As ready to connect installation components, Weigh Cells supply final weight values via a CAN interface as standard. Other supported interfaces are EtherNet/IP, EtherCAT, Profinet IO and Powerlink.

What is the difference between a tension load cell and a compression load cell?

Tension (tension force) load cells

With load cells the load is usually applied from above. Wipotec Weigh Cells, however, operating on the principle of electromagnetic force restoration (EMFR), can also be used to measure tension forces. Load application from above is then replaced by tension force from below. To measure tension loads, Wipotec Weigh Cells are mounted upside down. The product to be weighed can then be suspended directly from the Weigh Cell in load direction.

Tension (tension force) load cells are used for static weighing tasks in the process industry and for conveying applications and high-precision dosing. These include measuring the filling level of suspended containers. With the appropriate interfaces, the weighing electronics provide digital weighing results for the most common process management systems.

Compression load cells

Compression load cells are among the most common types of load cells. Compression load cells are usually positioned under the object to be weighed. In Wipotec Weigh Cells measuring compression loads, the compression load acts on one side of a mechanical beam balance. The other side of the lever arm is fixed by a plunger coil. The current required to compensate the lever arm is proportional to the compression load. Converted into a digital signal, it is processed in digital evaluation electronics. With sampling rates of 1000 measured values per second, Wipotec Weigh Cells are among the fastest EMFR compression load cells for industrial use.

Due to their operating principle, Wipotec Weigh Cells measuring compression loads offer high resolutions and good repeatability with shortest measuring times. An integrated test weight permits a self check at any time to verify the EMFR load cell's functionality Depending on specification, EMFR compression load cells from Wipotec also meet the wash down specifications according to IP65 and IP69K. Wipotec Weigh Cells can measure very small weight forces precisely. They are therefore also used in precision scales as well as in analytical and microbalances.